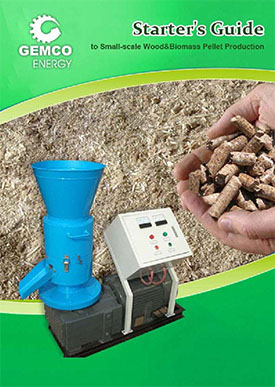

Pellet Press

With the fast development of feeding animals industry and biomass energy saving project, the small scale pellet press or pellet mill become very popular.For the reason it they can not only process the feedstuff for animals, such as feed for fish, chicken, pig etc, but can also change waste biomass materials into useful wood pellets. At the beginning, the small scale pellet presses mainly used to process the pellet as feedstuff, however, as to make it to process the waste biomass material such as sawdust, straw etc. people change the press through improving the quality of its main parts in recent years.Now, the improved pelletizing machine can successfully process wood pellets, even making wood pellets with high quality. The final wood pellet can be burned as green fuel in pellet stoves or boilers.

Benefits of Wood Pellets

One way to improve the energy density of wood fuel is to convert it into wood pellets. Ideally this is undertaken at the material processing facility.

Wood pellets have several distinct advantages when compared to wood chips:

Greater energy density

Relatively clean

Better flow

Low moisture and ash content

Consistency

Less volume to transport and store

Smaller and cheaper boiler systems

Raw Material to Make Pellet:

Any type of Agro-Forestry waste could be used to make pellets by pellet presses. But the Moisture Content Should be Less than 12%, grain size is below 5×5mm.

Groundnut-shell • Sugarcane residue• Caster Shells/Stalk • Sawdust • Coffee Husk • Paddy Straw • Sunflower Stalk • Cotton Stalks • Tobacco waste Mustard Stalk • Jute waste • Bamboo Dust • Tea waste • Wheat Straw • Palm husk • Soybeans husk • Rice Husks • Forestry wastes • Wood Chips and many other Agro wastes.

Key Parts

Sharing our experiences:

For using this flat die pellet press, we got some feedback from our customers. They obtained some experience when they were using this machine to produce wood pellet. Hope it is helpful for you:

1) Best moisture is 15% for all materials

2) The temperature is constant about 90-95'C, you have to take over the pellet just coming out from this pellet press and cooling it before touching it by hand.

Modifies on the machines:

Furthermore, we improved our machine more suitable to produce wood pellets after absorbing & digesting the feedback from our customers. In general, they are as follows:

1) Special raw material on the main parts such as roller, template, matrix

Prolonging the life than other similar products in China when process wood pellet after this modification.

2) Modify the whole in the matrix to improve performance of the machines. It’s more easy to make pellet.

3) We got the CE Certificate to meet EU client’s requirement on the safe and electricity implements.

Pellet Production Process

Pellet production is ideally suited for processing of dry material with low moisture content of less than 12% and for material which is not suitable to be made into wood chips. Typically the pellet production process consists of the following stages:

Milling - Raw material is reduced to a particle size of about 3mm and heavy woody elements are removed.

Conditioning - Material is prepared to the right moisture content and temperature.

Pressing - The woody material is fed into the pellet press. Pellets are formed by forcing the material through a die to achieve compaction.

Cooling - The wood pellets need to be cooled after leaving the press. By cooling the pellets this ensures that they harden, making them more robust during storage and handling.

Screening - Pellets are passed over a vibratory screen to separate fines.

Storage - Pellets need to be protected against rain. Storage time is unlimited.

Technical Parameter

1.Pellet press with electric motor

|

Type |

Power (Kw) |

Capacity |

Dimension (mm) |

NG/GW |

|

ZLSP200B |

3-phases 7.5kW |

200-300 |

1000x430x950 |

200/230 |

|

ZLSP200B |

200-300 |

900x430x950 |

|

|

|

ZLSP230B |

3 phases 11kw |

300-400 |

1140x470x970 |

290/320 |

|

ZLSP230B |

300-400 |

980x470x870 |

|

|

|

ZLSP260B |

3 phases 15kw |

400-600 |

1200x500x1070 |

330/360 |

|

ZLSP260B |

400-600 |

1120x490x1070 |

|

|

|

ZLSP300B |

3 phases,22kW |

700-800 |

1270x520x1070 |

410/450 |

|

ZLSP300B |

700-800 |

1170x520x1070 |

|

|

|

ZLSP360 |

3-phases 22kW |

|

1270x520x1070 |

470/500 |

|

ZLSP360 |

|

1270x520x1070 |

|

|

|

ZLSP400 |

3 phases,30KW |

900-1100 |

1470x600x1150 |

550/585 |

|

ZLSP400 |

900-1100 |

1470x600x1150 |

|

2. Pellet press with diesel motor

|

Type |

Power (Kw) |

Capacity |

Dimension (mm) |

NG/GW |

|

ZLSP200A |

15hp diesel |

200-300 |

1000×460×900 |

210/240 |

|

ZLSP200A |

200-300 |

1000×460×900 |

|

|

|

ZLSP230A |

22Hp diesel |

300-400 |

1180x560x1020 |

280/310 |

|

ZLSP230A |

300-400 |

1090x520x820 |

|

3. Smallest pellet press

All models above can process both animal feedstuff and wood pellet from sawdust. If you only use the machine to produce feedstuff, there are four smaller models for your reference as follows:

|

Type |

Power (Kw) |

Capacity |

Dimension (mm) |

NG/GW |

|

ZLSP120 |

3kw 3-phases or 2.2 kw single phase |

75-100 |

710x390x910 |

80/100 |

|

ZLSP120 |

75-100 |

670x390x910 |

|

|

|

ZLSP120A |

8hp diesel |

75-100 |

730x320x670 |

|

|

ZLSP120A |

75-100 |

900x440x730 |

120/140 |

|

|

ZLSP150 |

4kw 3-phase |

90-120 |

750x350x650 |

95/115 |

|

ZLSP150 |

90-120 |

700×350×650 |

|

4. CE Series Pellet Press

|

Type |

Power (Kw) |

Capacity |

Dimension (mm) |

NG/GW |

|

ZLSP200(D-TYPE) |

3-phases 7.5kW |

200-300 |

1000x430x950 |

200/230 |

|

200-300 |

900x430x950 |

|

||

|

|

3phases,22kW |

700-800 |

1270x520x1070 |

410/450 |

|

700-800 |

1170x520x1070 |

|

5. Different color machines made according to customer’s requirements.

FAQ for pellet presses

1. What is a Pellet Press?

Pellet presses, also known as Pellet mills are used for the compression of dusty materials into solid pellets. These pellets, sometimes known as bio-pellets or fuel pellets, can be used as fuel for heating.

2. How big is a pellet press?

Pellets presses / pellet mills are available in from 7.5 kW to 30 kW.

3. What can the pellets used for?

Pellets can be used in the production of animal feeds, or as fuel pellets for use in a pellet stove or boiler.

4. What are the pellets made from?

Pellets can be made from wood / sawdust/ plastic / foam / wheat / barley / cotton and fibre waste. They also need a wet ingredient, such as steam or molasses.

5. How are the pellets made?

The pellets are made by compacting the mash or meal into many small holes in a die. The die is usually round and the pellets are pushed from the inside out or opposite.

6. What size pellets are produced?

The length and diameter of the pellets are adjustable according to the size of the die in the pellet press.

7. What is the cost of a pellet press?

Different capacity, different price.

8. How do you deliver the pellet presses?

Transport and worldwide shipping is available.

9. Are the pellet presses new or used?

All machines are used with warranty available, advice is free.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).Our professional team will reply to you within one business day.Please feel free to contact us!